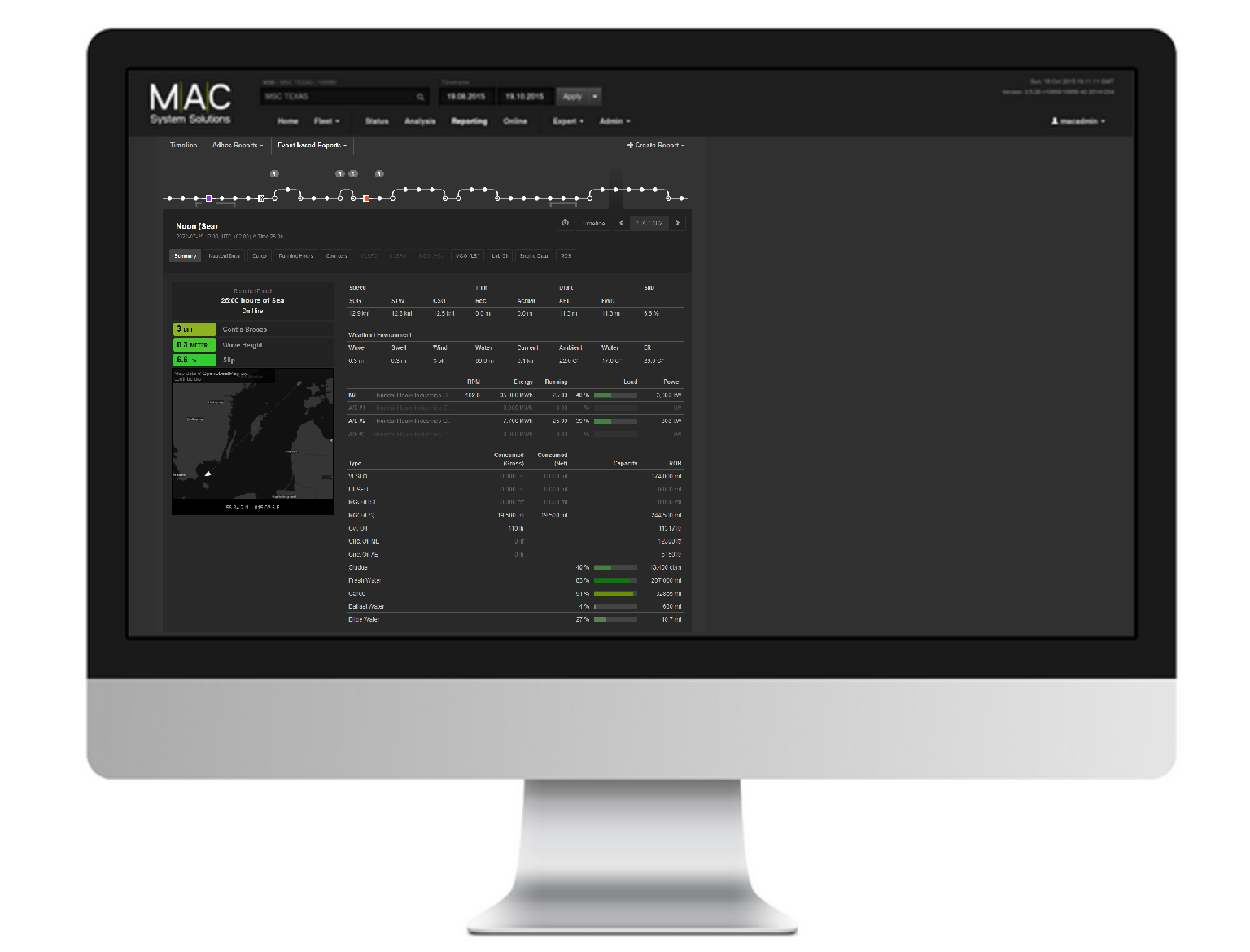

Reporting

Our SDBnet high-end reporting system will reduce friction and delays when performance relevant data are needed. The logical checks help to reduce mistakes when manual input is done by the crew.

The reporting is broken down into two categories: The “event-based reporting” covers the daily business routines also known as noon-reporting. Additional “ad-hoc reports” document processes like bunkering, sludge disposal and scheduling.

The reported data fulfill the requirements of an advanced ship performance monitoring and also fully cover all emission regulations (EU MVR, EU ETS, Fuel EU Maritime, IMODCS / CII).

Automatic data logging

Our solution offers you the flexibility to record data not only at 15-minute intervals but also, upon request, at 1-minute intervals. This higher recording frequency allows for a more detailed and precise analysis of your data. In addition to this, the data can also be transmitted live upon request, enabling real-time monitoring and analysis. This feature ensures that you are always up to date with the latest developments and can respond immediately to any changes.

By providing data at 1-minute intervals, you can capture more granular insights, which is particularly beneficial in scenarios requiring high-resolution data. Whether you're monitoring environmental conditions, tracking energy consumption, or managing complex industrial processes, the ability to adjust the recording interval to 1 minute offers significant advantages in terms of data accuracy and responsiveness.

Moreover, our live data transmission capability ensures that you have access to the most current information as it happens. This real-time data flow is crucial for making timely decisions, optimizing performance, and mitigating potential issues before they escalate. Whether you need to monitor critical infrastructure, ensure the smooth operation of production lines, or keep a close eye on key performance indicators, our solution provides the tools you need for effective and proactive management.

Electrical Energy Monitoring

Energy monitoring is increasingly an important source of information for energy optimization and for reducing operating costs.

In order to process a high number of signals, EMSnet provides modular components keeping installation cost down. Integrating all suppliers and consumers providing a comprehensive view of energy flow and distribution as utilized by your vessel.

Our Electrical Energy Monitor EMSnet enables you to comply with Marine Environment Protection Committee recent published guidelines on correction factors and voyage adjustments for CII calculations MEPC.328(76).

Typical source for the energy monitoring are:

Auxiliary engines

Shaft generators

Reefers -> MEPC.328(76)

E/R and cargo hold venting

Pumps for circ. oil, ballast water, ...